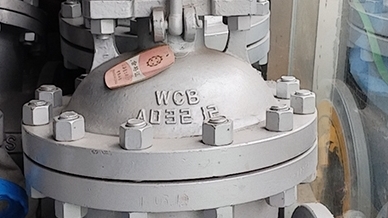

閥門是流體輸送系統中的控制部件,具有截止、調節、導流、防止逆流、穩壓、分流或溢流泄壓等功能。閥門種類繁多,有電動閥門、氣動閥門、液動閥門、手動閥門等。閥門可用于控制空氣、水、蒸汽、各種腐蝕性介質、泥漿、油品、液態金屬和放射性介質等各種類型流體的流動。閥門根據材質還分為鑄鐵閥門、鑄鋼閥門、不銹鋼閥門、鉻鉬鋼閥門、鉻鉬釩鋼閥門、雙相鋼閥門、塑料閥門、非標訂制閥門等。

Valves are control components in fluid conveying systems that have functions such as cutoff, regulation, flow guidance, prevention of backflow, pressure stabilization, diversion, or overflow pressure relief. There are various types of valves, including electric valves, pneumatic valves, hydraulic valves, manual valves, etc. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil products, liquid metals, and radioactive media. Valves are further divided into cast iron valves, cast steel valves, stainless steel valves, chromium molybdenum steel valves, chromium molybdenum vanadium steel valves, duplex steel valves, plastic valves, non-standard customized valves, etc. based on their materials.

閥門的選擇需要考慮多種因素,包括流體的性質、工作壓力和溫度、操作方式、安裝位置等。不同類型的閥門適用于不同的場合。例如,截止閥適用于需要頻繁啟閉的場合,閘閥適用于需要大口徑和高壓的場合,球閥適用于快速啟閉和流體調節的場合,蝶閥適用于大口徑低壓的場合,安全閥適用于需要防止超壓的場合等。

The selection of valves requires consideration of various factors, including fluid properties, working pressure and temperature, operating mode, installation position, etc. Different types of valves are suitable for different occasions. For example, globe valves are suitable for situations that require frequent opening and closing, gate valves are suitable for situations that require large diameters and high pressures, ball valves are suitable for situations that require quick opening and closing and fluid regulation, butterfly valves are suitable for situations with large diameters and low pressures, and safety valves are suitable for situations that require prevention of overpressure.

閥門的安裝和維護也需要注意一些事項。首先,閥門的安裝位置應該便于操作和觀察,同時要考慮流體的流向和閥門的啟閉方向。其次,閥門應該安裝在支架上,避免受到管道重量和應力的影響。在安裝過程中,要注意閥門的密封性和緊固件的緊固力矩,確保閥門能夠正常工作。在使用過程中,要定期檢查閥門的密封性、操作靈活性和外觀,及時發現并處理問題。

The installation and maintenance of valves also require some precautions. Firstly, the installation position of the valve should be easy to operate and observe, while considering the flow direction of the fluid and the opening and closing direction of the valve. Secondly, valves should be installed on brackets to avoid the influence of pipeline weight and stress. During the installation process, attention should be paid to the sealing of the valve and the tightening torque of the fasteners to ensure that the valve can function properly. During use, it is necessary to regularly check the sealing, operational flexibility, and appearance of the valve, and promptly identify and address any issues.

除了以上提到的閥門類型和安裝維護事項外,還有一些閥門的專業知識需要了解。例如,閥門的流量系數是指閥門在全開狀態下,流體通過閥門的流量與閥門面積的比值,它是衡量閥門流通能力的重要指標。閥門的公稱壓力是指閥門在正常工作條件下所能承受的最大壓力,它是閥門選用的重要依據。此外,閥門的密封性能、操作力矩、材料耐腐蝕性等都是閥門選用和維護過程中需要考慮的因素。

In addition to the valve types and installation and maintenance matters mentioned above, there are also some professional knowledge of valves that need to be understood. For example, the flow coefficient of a valve refers to the ratio of the flow rate of fluid passing through the valve to the valve area when the valve is fully open. It is an important indicator for measuring the flow capacity of the valve. The nominal pressure of a valve refers to the maximum pressure that the valve can withstand under normal working conditions, and it is an important basis for valve selection. In addition, the sealing performance, operating torque, and material corrosion resistance of the valve are all factors that need to be considered in the selection and maintenance process of the valve.

隨著科技的不斷進步和工業的快速發展,閥門的應用范圍越來越廣泛,對閥門性能和質量的要求也越來越高。因此,閥門制造企業需要不斷創新和研發,提高閥門的性能和質量,滿足市場和用戶的需求。同時,用戶也需要不斷學習和了解閥門的專業知識,正確選用和維護閥門,確保流體輸送系統的安全和穩定。

With the continuous progress of technology and the rapid development of industry, the application range of valves is becoming more and more extensive, and the requirements for valve performance and quality are also increasing. Therefore, valve manufacturing enterprises need to constantly innovate and research and develop, improve the performance and quality of valves, and meet the needs of the market and users. At the same time, users also need to constantly learn and understand the professional knowledge of valves, correctly select and maintain valves, and ensure the safety and stability of fluid conveying systems.

企業公告:

企業公告: